Refining node seeding at the gate location can further improve mesh quality which ultimately leads to better accuracy of simulation analyses. Moldex3D R13.0 Designer supports auto-refine function for curvature and proximity to correct mesh defects firsthand. Then, users may use “Modify node seeding†feature to manually refine node seeding at the gate location or other segments of the mesh to further enhance mesh quality for a more robust simulation analysis.

Step 1. Click![]()  and

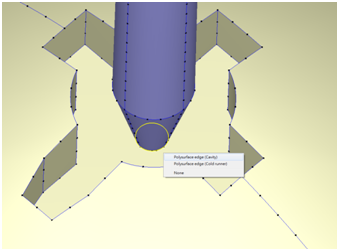

and ![]()  in the first dialog to apply default size setting. As shown below, the node distribution quality is overall good. However it is suggested to refine the node seeding at the gate location to further improve the mesh quality and analysis results.

in the first dialog to apply default size setting. As shown below, the node distribution quality is overall good. However it is suggested to refine the node seeding at the gate location to further improve the mesh quality and analysis results.

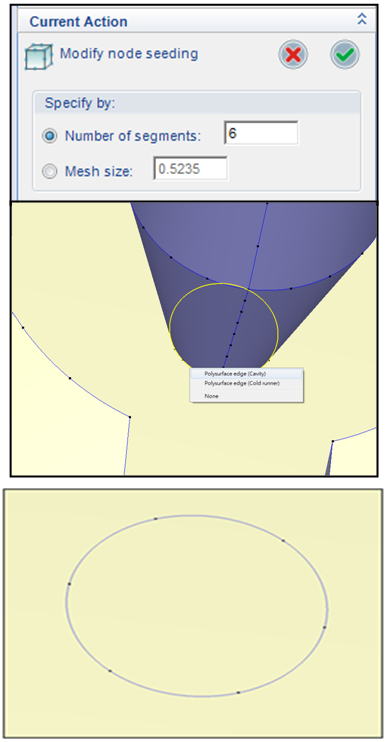

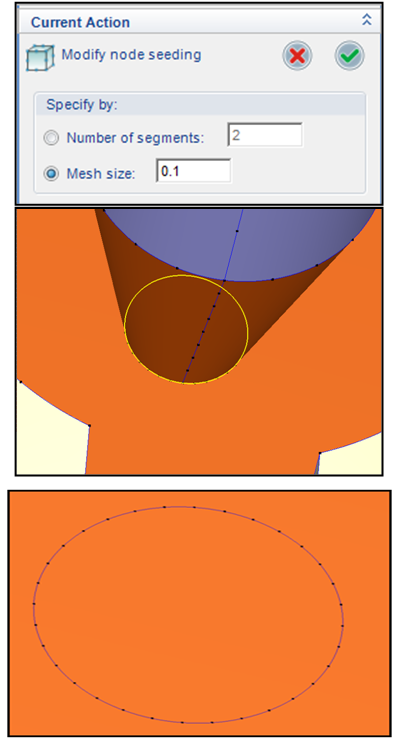

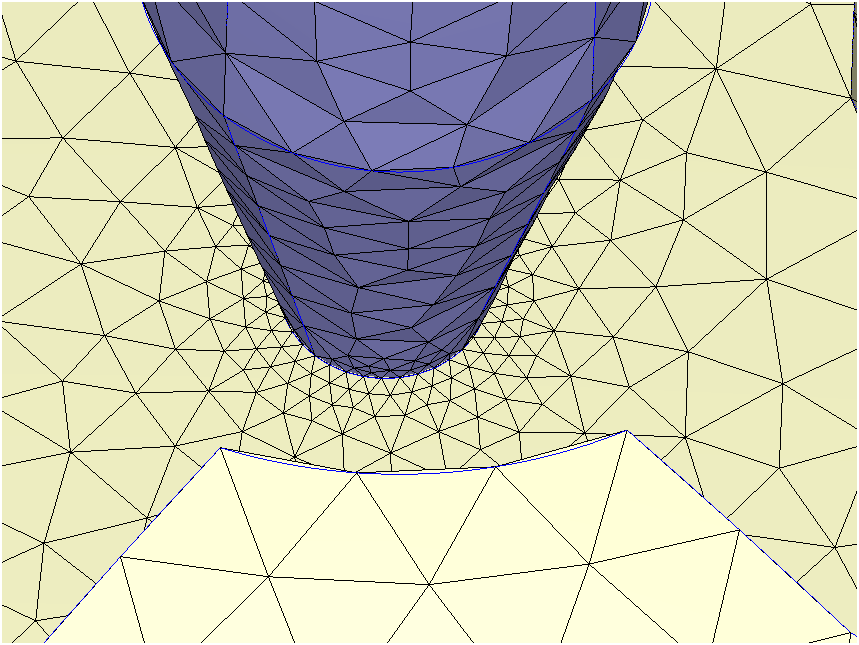

Step 2. To increase the number of nodes at the gate location, the second dialog enables users to locally refine the node seeding. In this dialog, choose the segment where the cavity connects to the runner to manually refine the node seeding. Specify seeding parameter in this segment and click “Enter†to apply

(Important! Do not click  ![]()  ). The new refined node distribution can then be seen as below.

). The new refined node distribution can then be seen as below.

|

|

Before manually refine the node seeding |

After manually refine the node seeding |

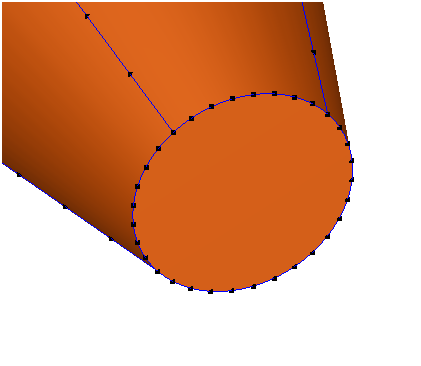

Step 3. Repeat Step 2 in the segment where the runner (not cavity) connects to the cavity (not runner) to manually refine the node seeding. Make sure the node distribution set in Step 2 & 3 matches with each other and then click![]() to apply a new size setting. Based on the refined node seeding, the mesh quality is further improved as shown below.

to apply a new size setting. Based on the refined node seeding, the mesh quality is further improved as shown below.

|

The flat sheets are processed using a dedicated high-precision fully automatic uncoiling, leveling and shearing production line to achieve high precision, low stress (six-fold precision leveling), full protection (online double-sided lamination), and traceability (online laser marking) of thin sheets )'s automated flow operation ensures high-quality full stress relief from coiled plate to flat plate and flatness of the plate before forming.

The only intelligent visual inspection system for plates in the industry can automatically identify all through-cracks and micro-cracks on plates, automatically detect corrugation depth deviations, and automatically detect all unqualified plates, ensuring zero defects in factory products.

Our company operates heat exchanger products: Plate Heat Exchanger, Heat Exchange Unit, welcome to consult.

Plate Heat Exchanger T Series,Brazed Plate Heat Exchanger T Series,Plate Type Heat Exchanger Y Series ,Welded Plate Heat Exchanger

Siping Juyuan Hanyang Plate Heat Exchanger Co., Ltd , https://www.tj-heatexchange.com